- Email: isotank@sytankcontainer.com

- Tel: +86-371-55526135

Long-distance transportation and temporary storage properties for liquefied natural gas.

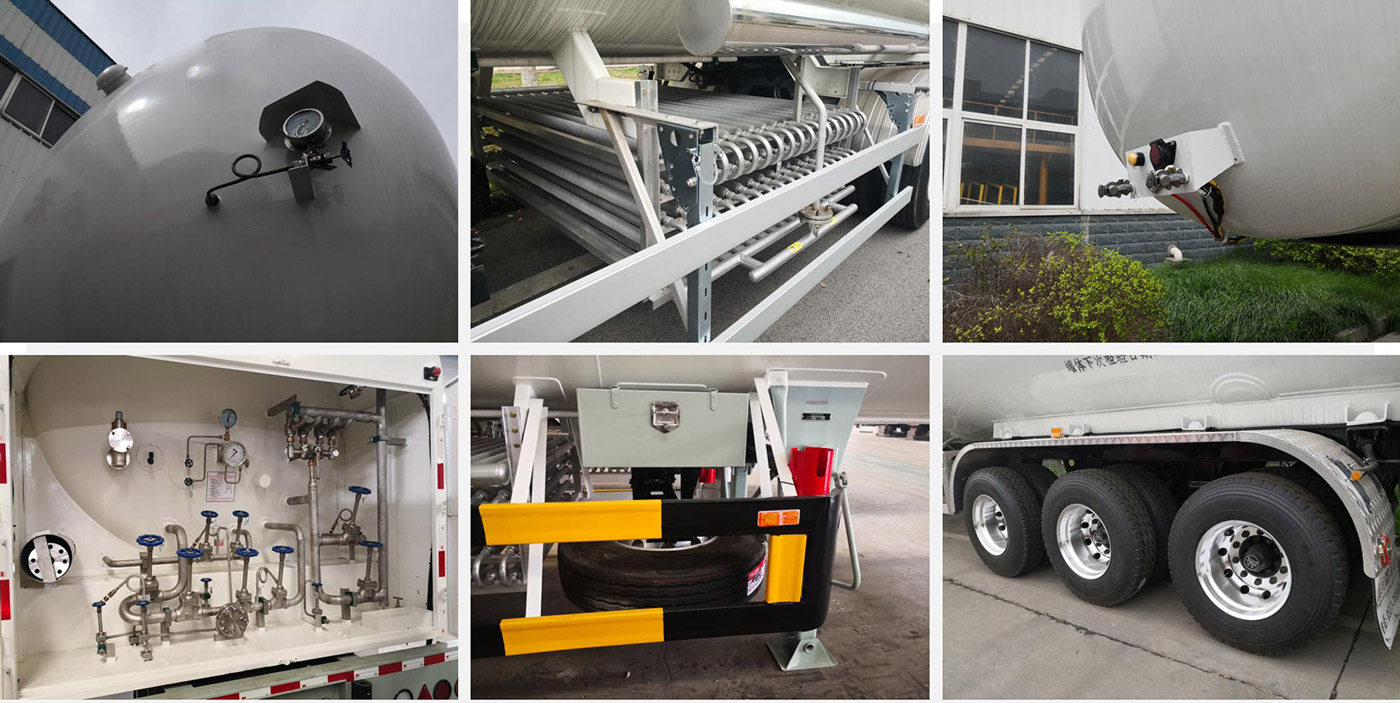

1.Integrated design of semi-trailer, tank body and pipeline system, with high safety performance.

2. The operating valves and instruments are arranged in the operating cabinet.

Long-distance transportation and temporary storage properties for liquefied natural gas.

1. Integrated design of semi-trailer, tank body and pipeline system, with high safety performance. 2. The operating valves and instruments are arranged in the operating cabinet.

3. The tank body is made of double-layer containers, and the interlayer has sound insulation performance.

4. There are vertical and horizontal types, with capacities ranging from 30Nm³ to 300Nm³. Applications For cryogenic liquid transportation and short-term storage.

Larger loading capacity, optional self-pressurization system to reduce energy consumption

2. Simple and convenient operation and maintenance

3. Has sound insulation performance

1. TSG RO005-2011 "Mobile Pressure Vessel Safety Technology Supervision Regulations".

2.GB150.1150.4-2011 pressure vessel

3. JB/T4783-2007 "Cryogenic Liquid Road Tanker".

4. ADR regulations on transport equipment and transport operations

5. ASME Volume 12

| 1 | Product Standard | TSG R0005-2011, GB/T150.1~150.4-2011, JB/T4783-2007 | |||

| 2 | Total mass | 40000 kg | |||

| 3 | Maximum allowable filling volume | 24600kg | |||

| 4 | curb weight | 15400 Kg | |||

| 5 | Dimension | 13000*250*3920 mm | |||

| 6 | Wheebase | 7166+1310+1310mm | |||

| 7 | fill medium | LNG | |||

| 8 | Use ambient temperature | -162/-20 ~50°C | |||

| 9 | Tank volume | 52.6/7.9 (Mezzanine) m3 | |||

| 10 | Tank diameters | 2346/2492 mm | |||

| 11 | design pressure | 0.65-0.1/0.2MPa | |||

| 12 | set tempreture | -196/50 °C | |||

| 13 | Filling capacity per unit volume | ≤467.7kg/m3 | |||

| 14 | work pressure | 0.60/-0.1 MPa | |||

| 15 | Cylinder structure | 06Cr19Ni10(S30408)6mm | |||

| 16 | head structure | 06Cr19Ni10 (S30408)7mm | |||

| 17 | Shell barrel material | Q345R 4mm | |||

| 18 | Shell head barrel material | Q345R 8mm | |||

| 19 | Pressure test pressure | 0.87 MPa | |||

| 20 | Air tightness test pressure | 0.65 MPa | |||

| 21 | Nondestructive testing | RT、MT、PT | |||

| 22 | NDT ratio | 100%、20% | |||

| 23 | pressure after gas replacement | 0.07 MPa | |||

| 24 | Oxygen content in the tank | 0.40% | |||

| 25 | Thermal insulation method | High vacuum multilayer insulation | |||

| 26 | main structure | double layer | |||

| 27 | Cryogenic safety valve | DN25*2 | |||

| 28 | Cryogenic safety valve | DN10 *3 | |||

| 29 | Cryogenic emergency shut-off valve | DN50 * 1 | |||

| 30 | Cryogenic emergency shut-off valve | DN40 *1 | |||

| 31 | Cryogenic emergency shut-off valve | DN32 *1 | |||

| 32 | Differential pressure level gauge | 15KPa *1 | |||

| 33 | pressure gauge | 0~1.6MPa *1 | |||

| 34 | flame arrester | DN40 *1 | |||

| 35 | axle loading | 14 ton *3 | |||

| 36 | ABS | China Comey | |||

| 37 | Tire | 12.00R20 | |||

| 38 | leaf spring | 13*90*10 pieces | |||

| 39 | Tractor pin | 90# or 50# | |||

| 40 | Landing gear | 28T | |||

| 41 | Reamrk | Pictures for reference, customized available. | |||